A filter bag or dust bag is used to separate particles smaller than 10 microns, and the basis of the work is that the air that is separated in the cyclone part of its larger particles, enters the filter bag here due to the presence of small cones. On the surface of the filter, small particles can not leave the filter, but the air passes through it and goes to the outlet. This process continues until the surface of the filter is full of dust and air can not pass, here is a system Automatically or manually shake the filter dust to clean the filter. Cleaning is done in several ways.

Cleaning Operation

This is done by three methods: mechanical vibration, reverse air flow and jet pulse.

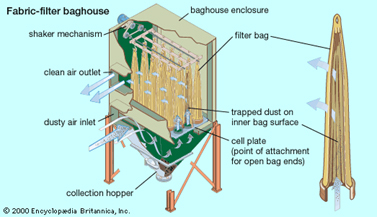

1. Mechanical Vibrator

In the mechanical shaking method, one side of the cylindrical bag filters is attached to a moving plate, which is vibrated by a motor, and thus the dust is removed by shaking the bag filters. . The air permeability ratio for this type of bag filters is very low and therefore requires a large number of bag filters and take up a lot of space.

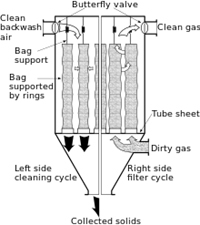

2. Reverse Airflow

In reverse air filters, known as industrial dust collectors, the end of the bag filters is attached to a metal plate and the other side is suspended from the top of the filter bag. Usually, this model of bag filters consists of several parts to be able to provide continuous operation of the filtration system. This type of bag filters also requires a lot of space.

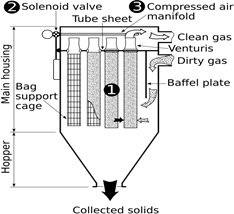

3. Jet Pulse

In pulse jet filtration systems, each bag filter is supported separately by metal cages. After the polluted air passes through the bottom of the filter bag chamber, dust and pollutant particles are trapped by the outer surface of the bag filters and the purified air comes out from the top of the filter bag. In this method, a compressed air jet pulse is used to clean the bag filters from dust particles.