Introducing Flash Dryer

Flash dryer is an industrial dryer in which materials enter the machine from the inlet section and are broken down into smaller particles by a mill. Hot air is blown from the bottom of the device and reduces the humidity of the material. In this process, particles that have less gravitational force than air resistance are removed from the device and directed to the cyclone. This device is used in various industries including food industry, food production and packaging. This device is very suitable for sticky food. In this article from Takado Sanat, we will get acquainted with the features and benefits of using a flash dryer device and examine its components together.

Advantages of using a flash dryer

In today's world, the use of flash dryers in industry has become commonplace. There are many benefits to using this type of dryer. In this section, we will get acquainted with some of the most important advantages of using flash dryers in different industries.

Improves product quality

- Flexibility in using this device to work with different dewatering systems and the possibility of using it for brittle and non-brittle wet foods

- Energy saving and the possibility of system integration

- Suitable for working with industrial solvents and their recovery

- Cost-effectiveness and reliability of this system, which rarely needs to be repaired, maintained and cleaned

- Flash dryer is suitable for regular changes in temperature

Flash Dryer Features

Flash dryers provide a convenient way to remove surface or unlimited moisture from the food product. Flash dryers are basically pneumatic dryers with variations in different configurations, but they all have a basic functional concept. In this section, we will mention some of the features of the flash dryer device.

- Short shelf life

- There is a retaining hopper or return mixing system in the machine that can be used if needed.

- This system can be designed for open circuit or partial gas recovery

- Flash dryer can be designed to operate in an inert atmosphere

- The flash dryer system is a simple system with few moving parts

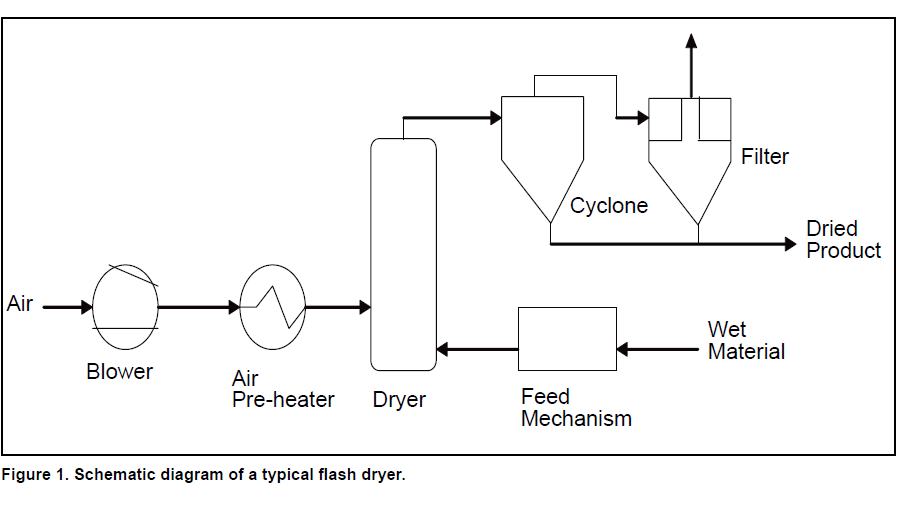

Components of Flash Dryers

There are different types of flash dryers, including elemental, ceramic and lamp; But apart from the type of device, the most important point in making flash dryers is the stabilization time (device speed), stabilization depth, power consumption and stabilization quality (do not burn the product paint and polish). The flash dryer itself consists of various components, which in this section we will refer to these parts and their function in the flash dryer device.

- The raw materials enter the feeding mechanism section

- The air is heated in a hot air generator or hot steam after passing through an air filter

- The radiator for raw materials puts its heat into the air stream and heats it

- Powdered materials that are mixed with hot air are transferred to the machine through a dry duct.

- The required pressure is generated by a blower or aspirator

- Materials lose their moisture through hot air. During this reaction, the air temperature decreases while the humidity increases

- Separation of the dried product and air is done in a cyclone. At this stage, the powder comes out of the cyclone through the powder discharge valves

- The tiny particles that come out of the cyclone were trapped in the bag filter

The exhaust air from the filter bag is dust-free and complies with the principles of pollution control

How the flash dryer works

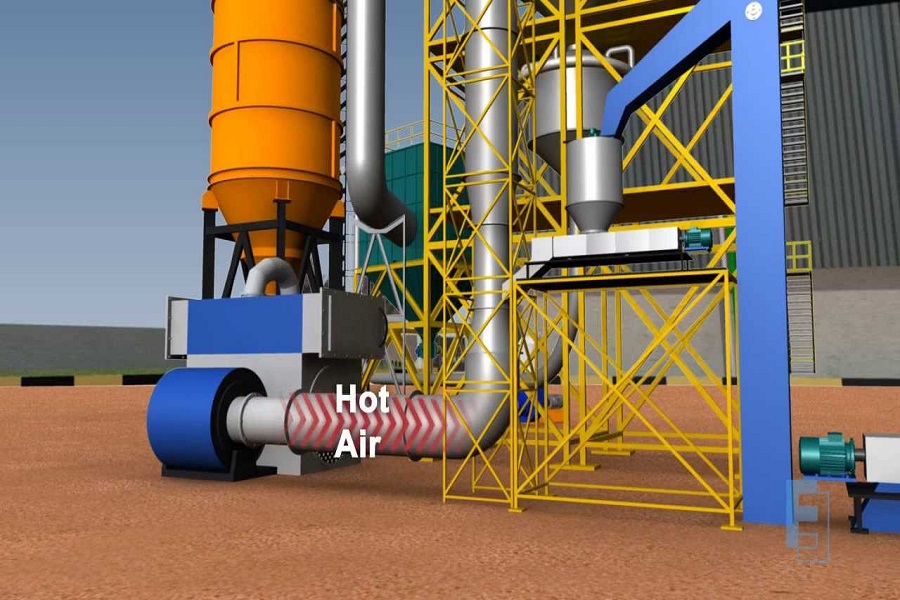

Flash dryers are an efficient way to dry the moisture of products such as slurries, pastes, crushed cakes, powders and granules. The size of the edible particles must be relatively large to allow transport without separation and aggregation. Flash dryers operate efficiently at operating power rates ranging from a few kilograms per hour to several hundred tons per hour (depending on the apparent density of the product). Depending on their operational capacity, there may be small pieces of equipment in the machine, which are imperceptibly located in the factory; Or they may need large, independent structures for support.

The product that is presented as the final product after the operation of the device may have residual moisture, which varies from 0 to 12% depending on the operating parameters or the limited moisture content of the food product.

Looking at the general function of the flash dryer, it can be said that the wet material is heated and dispersed in a stream of air, to which the gas is transferred through a drying duct. Using the heat of the air flow, the material dries during transfer. The product is separated using cyclones or bag filters. Cyclones are usually used by bag filters for the final cleaning of exhaust gases.

Uses of flash dryers

Exhaust gases can be used to increase heat efficiency and in cases where more inertia (density increase) is required. This partial gas recycle (PGR) configuration can be seen in all airflow drying systems.

Flash dryers are used to dry products in many industries, including agriculture, chemical and mineral industries. A wide range of foods such as powders, cakes, granules, flakes, pastes, gels and slurries can be processed with these devices. For adhesives, we need to re-mix the wet feed with part of the dry product to produce the right ingredients.

Buy the best quality flash dryer from Takado Sanat

In this article, we got acquainted with the features and operation of different components of the flash dryer device and its application in various industries such as food industry. You can order this device with different capacity, reasonable price and high quality from Takado Sanat and buy it. Flash dryer is one of the most important devices for food drying operations. That's why you have to buy it from a good dealer to be sure of its performance. By ordering this device from Takado Sanat, you no longer have to worry about the performance of your device and its originality.