Introducing Bag Filter

Bag filter or bag filter is a container that contains a number of bags made of polyester. As the dust-containing gas passes through the inlet valve and moves towards the filter outlet, the dust in it settles on the outer surface of the bags. Then, at certain intervals, by applying air pressure, the dust on the bag is shaken and poured into the lower chamber of the filter. In this way, the dust is separated from the gas. This system is widely used for air dust removal in the cement industry. In this article from Takado Sanat, we will get acquainted with the cases of using bag filters and we will introduce this system to you in full.

Advantages of using Bag Filter

There are many benefits to using a filter bag to clean the air. This system can be useful for various tasks. Also, the use of bag filters is very suitable in terms of environmental conditions. In this section, we will get acquainted with other benefits of using bag filters:

- High efficiency and efficiency in use

- Completely new and modern design

- A low-consumption device that optimizes energy consumption

- Low performance bag filter system

- Has repairable and replaceable parts

- Successful in environmental tests

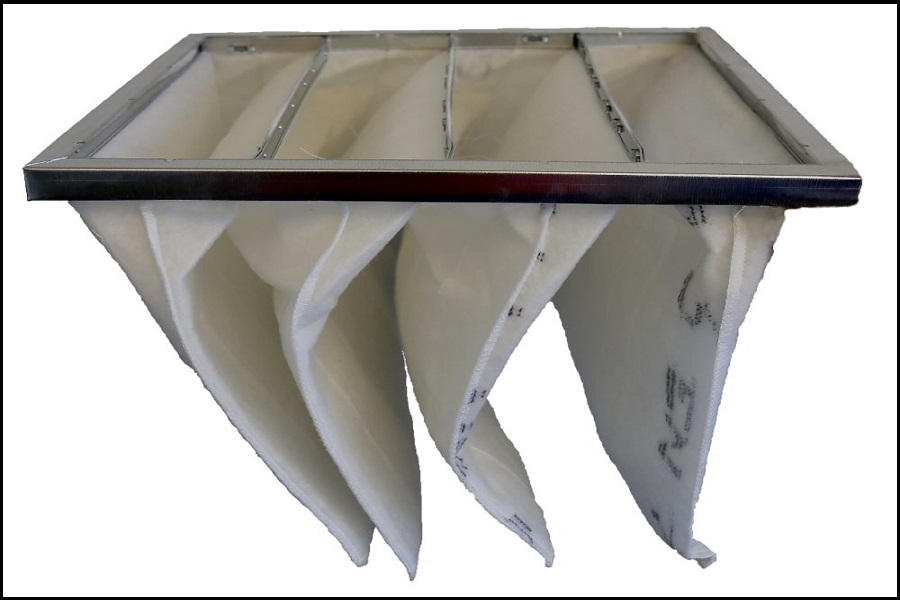

The appearance of the filter bag and its components

Bag filters usually consist of long cylindrical cloth bags. The surface of dust bags is a bag containing small cones that do not allow particles to pass through the surface of the filter bag. When air containing pollutant particles and dust enters the bag filter and passes through the filter surface, a layer of particles is formed on the filter surface; To the extent that air can no longer pass through the surface of the bag filter.

The cleaning system then goes into action and, online or offline, prepares the bag filter system for filtration. The filter bag consists of several components. These include the following:

- Bag filters and storage racks

- air compressor

- Centrifugal fan

- Collector hopper (bottom compartment of the device)

- Rotary-air lock Valve

- Bag filter cleaning system

- main body

- Silicone or igniter

- Solenoid valve

- Venturi

- Pulse jet control panel

- Fan

- air compressor

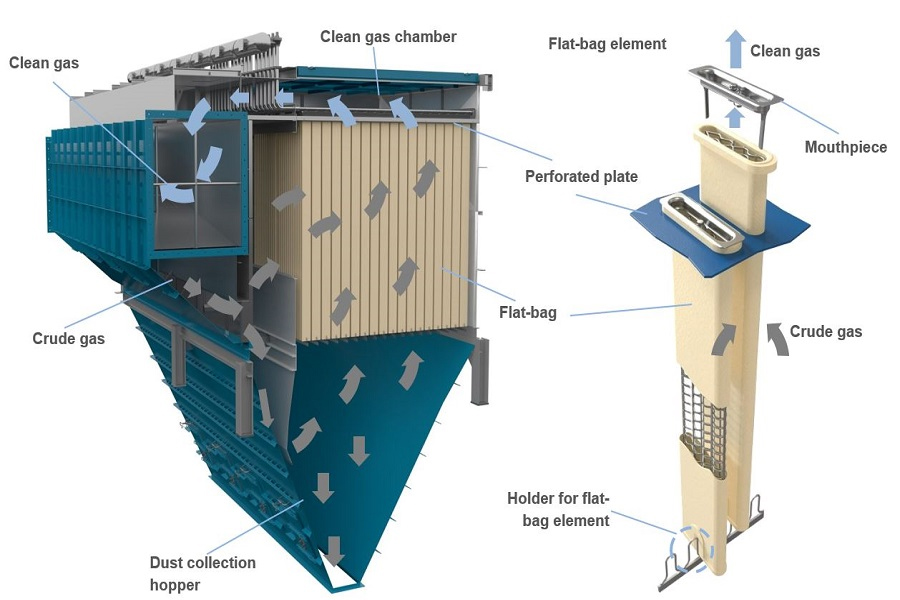

How the filter bag works

In dust filters or bag filters, the air carrying dust or smoke produced by polluting industries, after passing through the cyclone, goes to the bag compartment and after colliding with the bags and passing through them, it is cleaned. The clean air then enters the next chamber and is then sent to the chimney by the suction centrifuge fan. When filtering is continuous, the compressed air in the jet pulse is periodically blown into the bags by pulsed solenoid valves and nozzles through an electronically programmed panel, separating the material from the outer surfaces of the filter bag.

These isolated materials enter the hopper of the device and from there are directed to the outside of the device by transmission systems. Each row of filter bags is cleaned with a separate tube and nozzle installed in the upper part of the bags, using compressed air. For this purpose, compressed air tanks with complementary diaphragm valves are located at the end of each nozzle.

These diaphragm valves are operated periodically by an electronic controller. The compressed air that comes out of the device tank is blown into the bag through the blower nozzle tubes and the jet of the injector tube, which is located just above the bag and in the middle of the venturi. Even three-meter-long bags can be cleaned using this method. The use of bag filters can de-dust gases up to 20 mg / m3, which is very suitable for use in industry.

Different filtration methods by bag filter

The various methods used to clean bag filters include the three main commonly used mechanical vibration, reverse airflow, and pulse jet methods. In this section, we examine these three methods together.

Mechanical Shaking

In the mechanical vibration method, one side of the cylindrical bag filters is attached to a moving plate, which is vibrated by a motor, causing the bag filters to vibrate automatically, causing dust to escape from the filter bag. Air to Cloth Ratio is very low in this type of filter bag; So many more bag filters are needed. For this reason, a lot of space is required for such bag filters to work.

Reverse Air

In reverse air filter bags or industrial dust collectors, the end of the filter is attached to a metal plate and the other sides are suspended from the top of the bag filter. These types of bag filters are composed of several parts to allow continuous operation of the system. This system, like the previous system, requires a lot of space for implementation.

Pulse Jet

In a pulsed jet filtration system, the metal cages support the bag filters separately. Contaminated air enters from the bottom of the device compartment and dust is trapped by the outer surface of the filter bag. Purified air comes out of the top of the filter bag. Compressed air jet pulses are also used to clean bag filters.

Buy the original bag filter machine from Takado Industry

In this article, we got acquainted with the advantages of using the bag filter system, how this system works and the different filtration methods that are performed by this system. You can order this device with the capacity of different functions and with the best quality from Takado Sanat and buy it with confidence. Bag filter machine has very important applications in the industry; So it is better to buy it from a suitable center to be sure of the authenticity of our product. We suggest you to get help from our experts in Takado Sanat to choose your device and buy the best device according to your needs.