A condenser is a part in which a fluid changes phase and transitions from a vapor to a liquid state by transferring heat alongside another fluid, such as water or air, and heating. In fact, the fluid condenses and turns into a liquid.

What is a condenser?

What is the function of the condenser in the refrigeration cycle?

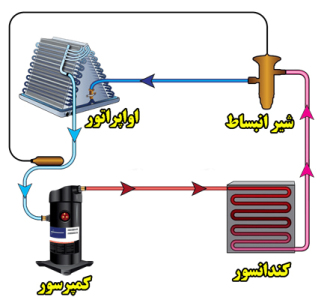

There are four main components to air conditioning systems that often use a compression refrigeration cycle. Compressor, condenser, evaporator and expansion valve.

The condenser in this cycle is responsible for taking heat from the refrigerant, converting it from gas to liquid and then transferring it to the expansion valve.

The main task of a condenser in a refrigeration cycle is to cool the refrigerant. The refrigerant enters the condenser after being compressed in the compressor and into a high-pressure hot gas state. The condenser cools this gas through water or air and tries to change its phase from gas to liquid at the same pressure by taking the latent heat of refrigerant.

Condensers can be very different in terms of performance and placement in different devices, but there are three general categories for these components:

- Air condensers or air coolers

- Water condensers or cold water

- Evaporative condensers

1. Air Condensers or Air Coolers

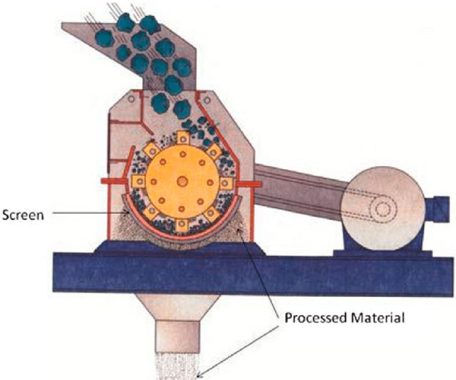

Other models of milling machines include the butterfly milling machine or the gear model. The basis of this device is the center rotating blades and gears embedded in the sides of the device. After entering the butterfly mill, the materials are placed between the blades and ribs and are ground by moving the blades. This machine is usually used to grind materials that are not very hard, such as vegetables, spices and also grains that are not hard. This type of mill is often used for industrial and semi-industrial purposes, and in large volumes.

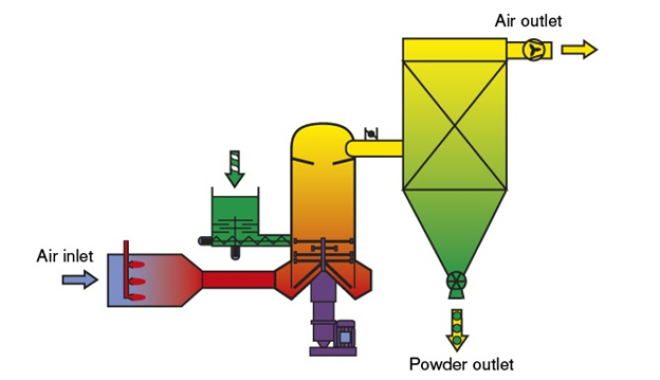

Spin Flash Dryer

Spin Flash Dryer is an ideal machine for continuous drying of cakes, slurries or dough, which is normally difficult to dry in other machines. The material is fed by a feeder into the dryer chamber, which is heated by hot air, and at the same time is broken into small pieces by a rotor. The dried powder is sucked in by a suction fan and collected by a silicone filter bag and, at best, both.

Products that can be produced in this device include organic and inorganic chemicals, pharmaceuticals, food, pigments and ceramics.

What are the types of condensers?

In this type of condenser, the refrigerant is cooled by water.

In this case, the hot refrigerant is placed by pipes near water. Water heating capacity is much higher than air, so devices with water condenser are more efficient than devices with air condenser.

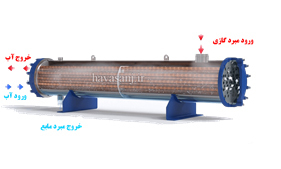

A very common type of water condenser used in chillers is the shell and tube model. This piece has a set of small diameter pipes that are inside a shell. The simplest type of condenser is a two-pipe type, in which a shell actually consists of only one pipe.

Shell and Tube condenser has a set of tubes and a shell around them. Usually water flows into the inner tubes and a liquid or gaseous refrigerant is placed in the shell. The proximity of the gas refrigerant to the water pipes causes the gas to lose heat and become liquid. The water that has taken the refrigerant heat for cooling again must either be completely replaced (for places such as the river) or it must be cooled again by another device called a cooling tower.

۲. Water Condenser or Cold Water

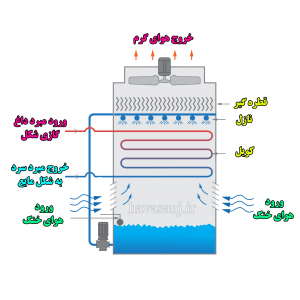

These condensers use both water and air to cool the refrigerant.

Water is sprayed from above on the pipes containing refrigerant and air passes from the bottom to the top through the condenser pipes. Water sprayed on pipes containing refrigerant may evaporate and the source from which the water is pumped and used as a spray on the pipes will need to be replaced.

3. Evaporative Condensers

Conclusion:

Condensers are one of the main components of the refrigeration cycle, without which the devices are practically unable to cool. Choosing the right type in a device is very important considering the environmental conditions and the cost and efficiency of the discussion. Water condensers are more efficient but not efficient in sultry areas. Air condensers need more care and attention, and their dust should be washed and their transportation should be more careful to prevent damage to these devices. The most famous condenser brands in the world are Thermokey and Thermokar. Of course, making condensers is not a very complicated task and in Iran, condensers are mostly produced by air conditioning companies.

Finally, we need to know that condensers have special properties and not every condenser can be used in every device and place.