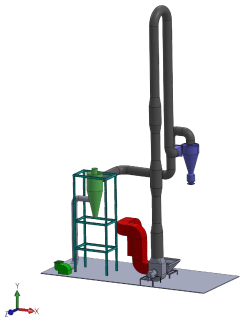

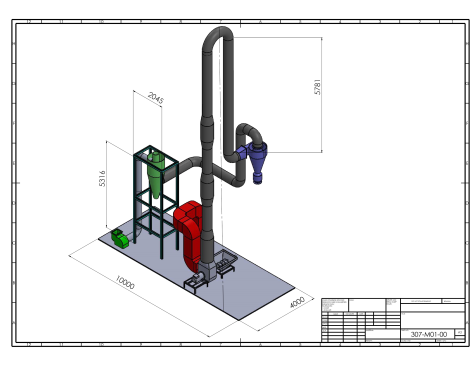

To dry powders, equipment called flash dryer is used intermittently. The following figure shows a schematic of a flash dryer. Initially, the moisture-containing powder is poured into a chamber containing hot air through a fine-duty screw, which is transferred to the chamber via a heat coil or steam or other means. Below this chamber is a propeller that is continuously Throws the powder upwards. The powder is fed by long tubes with negative pressure created by the sucker at the end of the line. Go to the cyclone, where the separation takes place. The dry powder is transferred from under the cyclone to a hopper. The air that comes out of the cyclone goes to a filter bag to perform the filtration operation. The clean air taken out of the filter bag is returned to the working cycle.