The mill is used for crushing and shredding in industry. Mills are made in different sizes and shapes according to the need. The important point in choosing mills is the group used in that mill, for example, the mill that is used to eat sugar or wheat flour can not be used to eat soy or foods containing fat particles.

In general, we have two types of mills in the industry: the vane mill and the hammer mill in the vane mill. , Almonds and ... have.

In hammers, hammering is done by striking food with hammer teeth. Hammer mills are used to pulverize grains, sugar, bran, etc.

A grinder is a device that can be used to pulverize or crush materials such as spices, food, dried plants, and so on. Industrial milling machines have differences such as dimensions, size, shapes, and so on. And are designed to be fully automatic. These devices do not produce a lot of dust and prevent wastage of products.

What are the Types of Industrial Mills?

Mills are divided into different types based on standing shape, desktop, capacity, application and mode of operation. Food industry mills are classified into pin mill, hammer mill, gear mill (butterfly), rocker mill, ball mill, jet mill and air class mill based on their performance. Each of these The devices have different uses and are designed for specific uses.

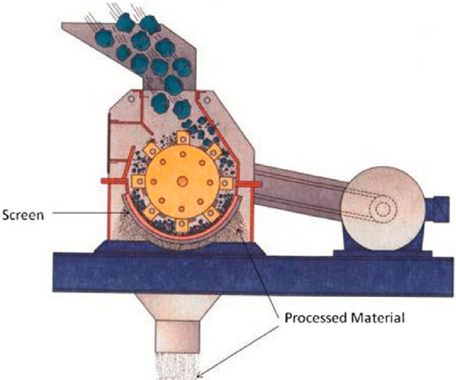

Hammer Mill Machine

The basis of hammer mill operation is fast-moving hammers. And the material is quickly pulverized by contact with these hammers. The hammer mill is basically a tropical steel container with a vertical or horizontal rotating shaft on which the hammer is mounted. The amount of pulverization of materials in hammer mills depends on the output of these mills and by changing the output mesh, the particle size of the product can be adjusted. This type of mill is made according to the application in different materials. Apparatus used for animal feed grains, for example, are often made of iron. If spice mills are made of stainless steel. The hammer mill is suitable for crushing hard and brittle materials.

Gear Milling Machine (Butterfly)

Other models of milling machines include the butterfly milling machine or the gear model. The basis of this device is the center rotating blades and gears embedded in the sides of the device. After entering the butterfly mill, the materials are placed between the blades and ribs and are ground by moving the blades. This machine is usually used to grind materials that are not very hard, such as vegetables, spices and also grains that are not hard. This type of mill is often used for industrial and semi-industrial purposes, and in large volumes.

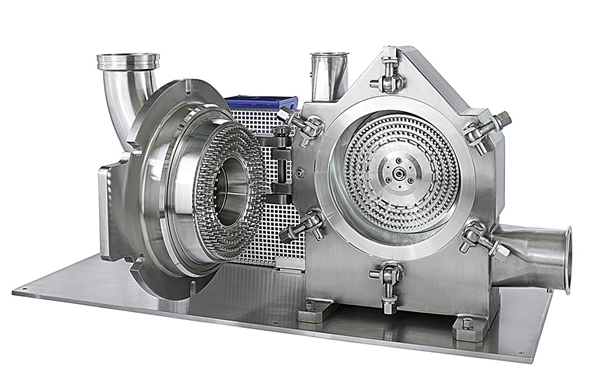

Pin Mill Machine

The basis of the operation of the pin milling machine is the pins embedded in the two rotating disks inside the machine. After entering the device, the material is placed between the pins of the two disks. By turning on the device, these pins repeatedly pass each other and disintegrate the material. The grinding ability of these devices is high and it is suitable for grinding various materials such as wheat, rice, cereals, sugar, hard and dry spices, dried herbs, dried vegetables and fruits, etc.

Cradle Milling Machine

The cradle mill is a model of industrial desktop mill that can be moved around a horizontal axis. The rocking capability of the milling machines is involved in better granulation of grains and easier emptying.

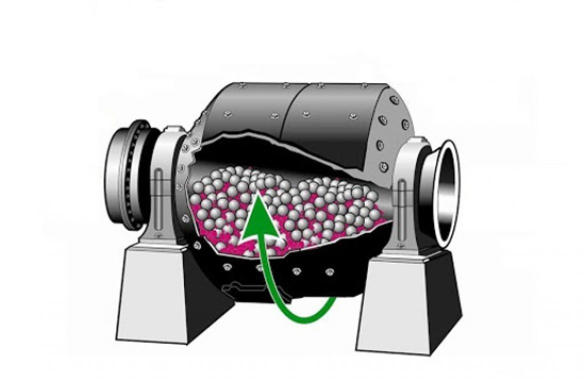

Ball Mill Machine

The basis of the operation of the ball mill is the presence of stone or steel balls inside the machine. These bullets can be used in different sizes. Once in the machine, the material is placed in a container with these balls or bullets. When the device is turned on, the chamber begins to rotate and the collision between this bullet in the container causes high local pressure and the material is ground.

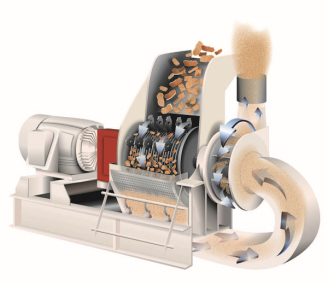

The jet mill uses a high-velocity jet of air or neutral gas to crush the material particles by colliding with each other. The particles in the device collide with each other at different focal points and thus are crushed. Because the particles are ground by contact with each other, the product is not contaminated. This mill can also grind particles with high hardness.

Jet Mill Mill

Air classification mill is a vertical mill that has two parts: material mill and their classification. This machine uses a pneumatic and centrifugal force system for the mill and then these particles enter the air classification section. In this way, the particles are accompanied by the air flow inside the system and are pushed down by gravity, as well as the pressure created by the classification mill. Thus the milled materials are classified according to weight.

Air Classification Mill Machine

In What Industries are Industrial Mills Used?

Types of milling machines have many applications in different industries. These devices are used in the pharmaceutical industry to produce tablets and powdered drugs. The industrial mill also has many uses in the food industry. Some food factories use industrial mills to pulverize and grind spices and raw materials used in their products. Flour, corn, wheat, barley, spices and other food factories also make extensive use of milling machines.